Terms and Conditions

CANCELLATION AND RETURN POLICY

Once an order has been placed for a manufactured item, it cannot be cancelled. All panel orders and special order (non-stock) trim are considered the property of the customer and are non-refundable once they have been manufactured. All goods are sold “AS IS”. Accessories are refundable as long as they are returned in a clean, re-saleable condition. Restocking charges may apply.

ORDER PROCESS

Customers must confirm all orders in writing via text, email, fax or in person.

PRICING

Pricing is subject to change without notice.

SALES TAX

All orders are subject to sales tax unless a current sales tax exemption certificate is provided to MFMRS prior to sale.

PAYMENT TERMS

- Payment is due in full at the time of placing the order

- Credit terms may be established at the sole discretion of the financial department of MFMRS. MFMRS reserves the right to deny credit without explanation.

- All credit accounts are required to complete a “Job Information” form or submit a recorded notice to owner on all material being supplied

ORDER ACCURACY

Purchaser assumes all responsibility for accuracy of order. All cut lengths and quantities are to be provided by purchaser and not based on comments or suggestions of any employee or representative of MFMRS.

STANDING SEAM MATERIAL ORDERS

A signed Standing Seam disclaimer will be required on all standing seam orders!

MISCELLANEOUS

- There will be a charge of $50.00 for any returned checks

- This contract shall be governed by and construed in accordance with laws of the state of Florida.

- Purchaser, by placing its order with seller, represents and warrants that purchaser is familiar with and in compliance with all laws and regulations applicable to its work, including all Florida Product Approval requirements and OSHA rules and regulations with specific reference to the safety standards for fall protection in the construction industry.

- Purchaser assumes all responsibility for applying county codes and guidelines applicable to work performed.

INFORMATION TO BE NOTED

Galvalume

Uniform visual appearance (color, spangle, shadow spots, and striping) of unfinished Galvalume(r), Acrylic Galvalume(r), Galvanized, Acrylic Galvanized, Aluminum, and Paint Grip panels cannot be guaranteed. If uniform appearance is desired, then prepainted Galvalume(r) or Galvanized should be ordered. Non-uniform surface appearance (color, spangle, shadow spots, and striping) may occur over time, it does not represent a deficiency in the material, nor does it affect any warranties which may be in place, and it is not a reason for rejection.

OIL CANNING

Oil canning can be defined as the actual waviness in the flat areas of roofing and siding panels. Generally the period and amplitude of the wave depend on the width of the flat. Oil Canning is an inherent condition with light gauge cold formed metal products, and can result from residual stresses induced or redistributed during coil production, slitting, perforating, forming or fabrication of steel products. Improper deck handling, installation or attachment to misaligned steel supports can also cause oil canning.

In general, oil canning is an aesthetic condition with no effect on the structural integrity of the deck. Since many uncontrollable factors can lead to oil canning, the manufacturer assumes no responsibility for the cost of actions taken in response to an oil canning condition. Oil canning shall not be a cause for rejection of material.

THINGS YOU SHOULD KNOW

Cutting panels:

- All material should be cut with nibblers, tin snips or a profile shear if available. You always want to make a shearing / pinching cutting action versus an abrasive cutting action from a circular saw. Although it is not the recommended choice of Mid Florida Metal Roofing Supply to use a saw for cutting we understand that many will still do so. There are two concerns when using a saw. First, be sure that no burrs are left on the ends of the panel. The rough edges are not protected and will rust. Second, the filings or shavings coming off of the blade are hot and will adhere to the surface of the panels and these will also rust. Be sure all filings and shavings are removed from the surface as they will rust and pit the material.

Corrosive / dissimilar materials to avoid:

- Graphite pencils should be avoided when marking panels. Graphite will corrode the metal and within a short period of time rust will form. Lead and Copper boots are also corrosive to Galvalume.

- Direct contact with pressure treated lumber and metal roofing must be avoided to prevent potential corrosion.

- Damage will result if uninstalled panels or trim are allowed to remain wet in storage. Be sure to store material that will not be installed immediately in a dry location. Wet material should be air-dried and re-stacked if installation is not planned right away.

- Nibblers, and especially Carborundum blades on electric saws, do have a tendency to either leave hot metal particles that can burn paint surfaces or leave rust marks on panels and trim. The same is true of any filings left on the roof caused by the application of screws. Care should be taken to brush all such particles from roof surfaces after application. CAUTION! clean all metal shavings and particles off of roof to avoid unsightly rust stains.

PICK UP DISCLAIMER NOTICE

- Mid Florida Metal Roofing & Supply sincerely appreciates your business. Unfortunately, our facility does not have the capacity to store material in the volume that we are producing. Therefore, it is important orders are picked up promptly after the first notification. We will make every attempt possible to notify you via the contact information provided.

- If product is not picked up within 15 business days from 1st notification that it is ready, storage fees will be added and calculated at $15 per day.

- After 30 business days, material becomes the ownership of Mid Florida Metal Roofing.

Ready to start?

Speak with our professional sales staff today. We are available to answer questions, provide estimates and start your order.

1. Call Today

(866) 479-8080

Sales representatives are standing by

2. Choose Your Metal Roof Panels

Residential, commercial and ag available

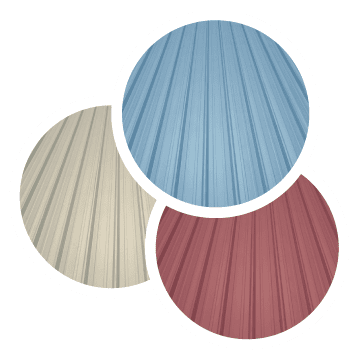

3. Select a Color for Your Roof

Preset colors and paint-able options

4. Determine Necessary Flashing Profiles

Standard sizes and custom trim pieces

5. Purchase Accessories for the Project

Screws, rivets, sealants and more

6. Pickup or Have Order Delivered

Delivering anywhere in the state of Florida