The Best Tools and Methods of Field Cutting Metal Panels

Most manufacturers cannot make your diagonal and specialty cuts for you, so cutting panels on site is a necessary part of metal roofing installation. To ensure your panels and flashing remain rust-free and smooth, it is very important to use the correct tools to make your cuts. Using the incorrect tools can result in rust, rust stains, voided warranties and decreased service life.

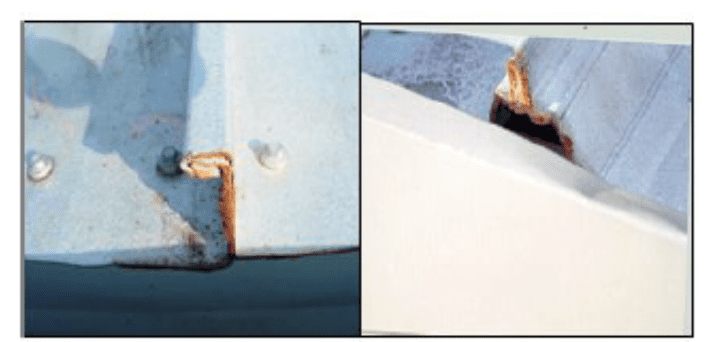

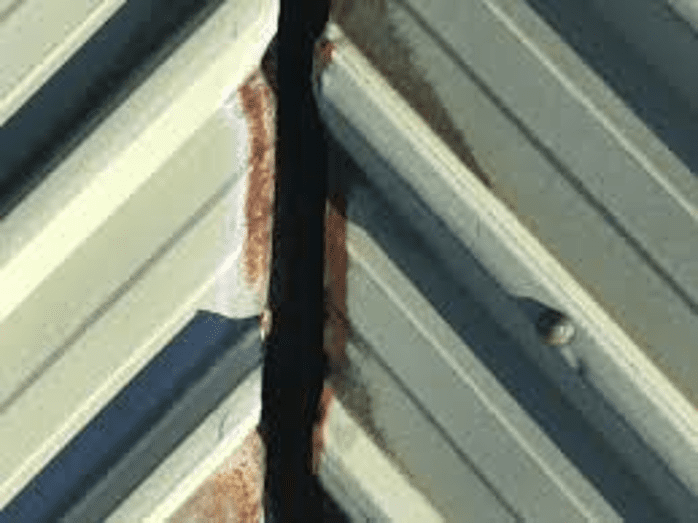

Premature corrosion and rust due to abrasive cutting of the panel

How to Maintain Longevity When Making Field Cuts

When metal panels are manufactured, the machines and methods used to cut the coated metal coil help protect the edge from corrosion. When cutting metal panels in the field, it is important to protect any cut edges. I know what you’re thinking… How can I protect my cut edges? In order to understand how to make field cuts without losing the protective quality of the material, you must first understand what protects the panels. Our panels are fabricated from Galvalume-coated steel coil. Galvalume protects the entire surface area of the panels. Galvalume has also been shown to be very effective along the thin edges of metal if those edges are cut properly.

In the fabrication process, our Galvalume metal panels are cut to the customers preferred length by shearing while flat before entering the roll former. This method will “wipe” the Galvalume coating over the edge of the metal panels providing a superior cut-edge protection from corrosion.

Therefore, when panels arrive on site, any field cutting should mimic the method used in the fabrication process to ensure protection of the cut edges. There are many ways to field cut metal panels and flashing that will maintain the protective coating on the cut edges. However, there are also many poor methods that lead to problems in the long run. Here are some examples of the Do’s and Don’ts…

Common Tools and Methods Used for Field Cutting Metal Panels

The best tools for cutting metal panels are aviation snips, electric shears, mechanical shears, and nibblers. It is important to use blades that cut cool. Using an abrasive blade can heat up the metal panel. When the Galvalume coating heats up or melts along the cut edge, it becomes ineffective.

Mid Florida Metal Roofing Supply carries the above shown Makita Nibbler and Wiss Hand Snips.

Additionally, it’s very important to avoid cutting panels on the roof or above other panels or materials. This is because some methods of cutting will throw tiny bits of steel debris into the air, landing on the panels below. This debris is commonly referred to as swarf. Swarf, if not removed immediately, will damage paint, rust and can lead to rust spots on your roof or in some cases even rust through the panel entirely.

Even using the proper tools doesn’t ensure that there will be no swarf. Swarf can even occur during screw installation. It is highly recommended that once a roof installation is complete, the entire roof be brushed off to ensure no remaining bits of shavings are removed.

Tools That Should Be Avoided When Field Cutting Metal Panels

Tools that you should NEVER use include torches, skill saws, cut-off saws, reciprocating saws, hacksaws, or grinders.

All these tools melt the Galvalume coating which causes rust and throw swarf (steel debris) onto the panels. This hot debris can become embedded into the panel coating causing rust spots and even rust that penetrates the panel completely.

In conclusion, be sure to use the correct tools and methods recommended by your manufacturer when cutting metal on site. This will make certain that the panels remain damage-free. Using the wrong tool or method can lead to rust, rust stains, and voided warranties. Make sure to clean roof surfaces after installation to remove all remaining debris that can cause issues as well!

See above – corrosion at cut edge due to improper tools

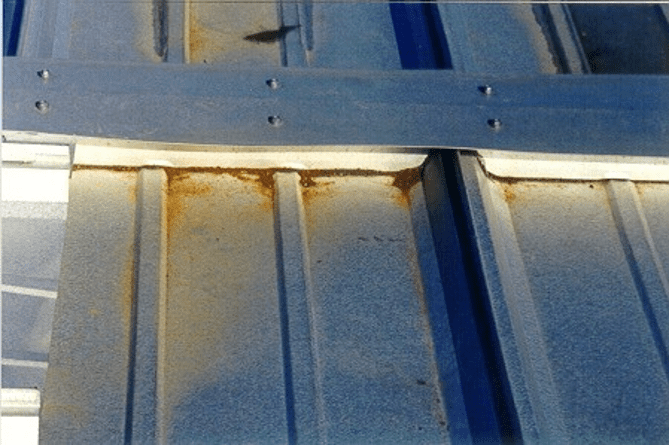

See above – rust stains due to swarf accumulation that was not removed

Proper installation techniques and tools are available at Mid Florida Metal Roofing Supply.

Contact your sales representative for more information and pricing!

About Mid-Florida Metal Roofing

Mid-Florida Metal Roofing Supply has been in the business for 16 years. MFMRS manufactures a wide variety of metal roofing products including; Multi-Rib (AG), PBR/R, 5V and Standing Seam in a Galvalume mill finish, as well as, a wide variety of colors to meet all your preferences.

We also manufacture an extensive list of flashing profiles to meet any standard or custom application as needed. We specialize in custom profiles serving a wide variety of needs in the construction industry. Our profiles can also be ordered in custom lengths up to 21ft.

We are committed to producing quality products in a timely manner and pride ourselves with friendly personal customer service.