Transforming a 1950s Home with Modern Standing Seam Panels

The charm of a 1950s home lies in its historical essence, the embodiment of a bygone era. However, the real challenge presents itself in maintaining this allure while ensuring the home meets contemporary standards of efficiency and style. This is where the magic of modern standing seam panels comes into play, especially for homeowners looking to blend classic aesthetics with modern functionality.

The Timeless Appeal of 1950s Architecture

Homes from the 1950s often feature distinctive architectural elements like low-pitched roofs, large windows, and an emphasis on horizontal lines. These characteristics present both a challenge and an opportunity when considering a roofing update. The key is to enhance functionality without detracting from the home’s original charm.

Why Choose Standing Seam Panels?

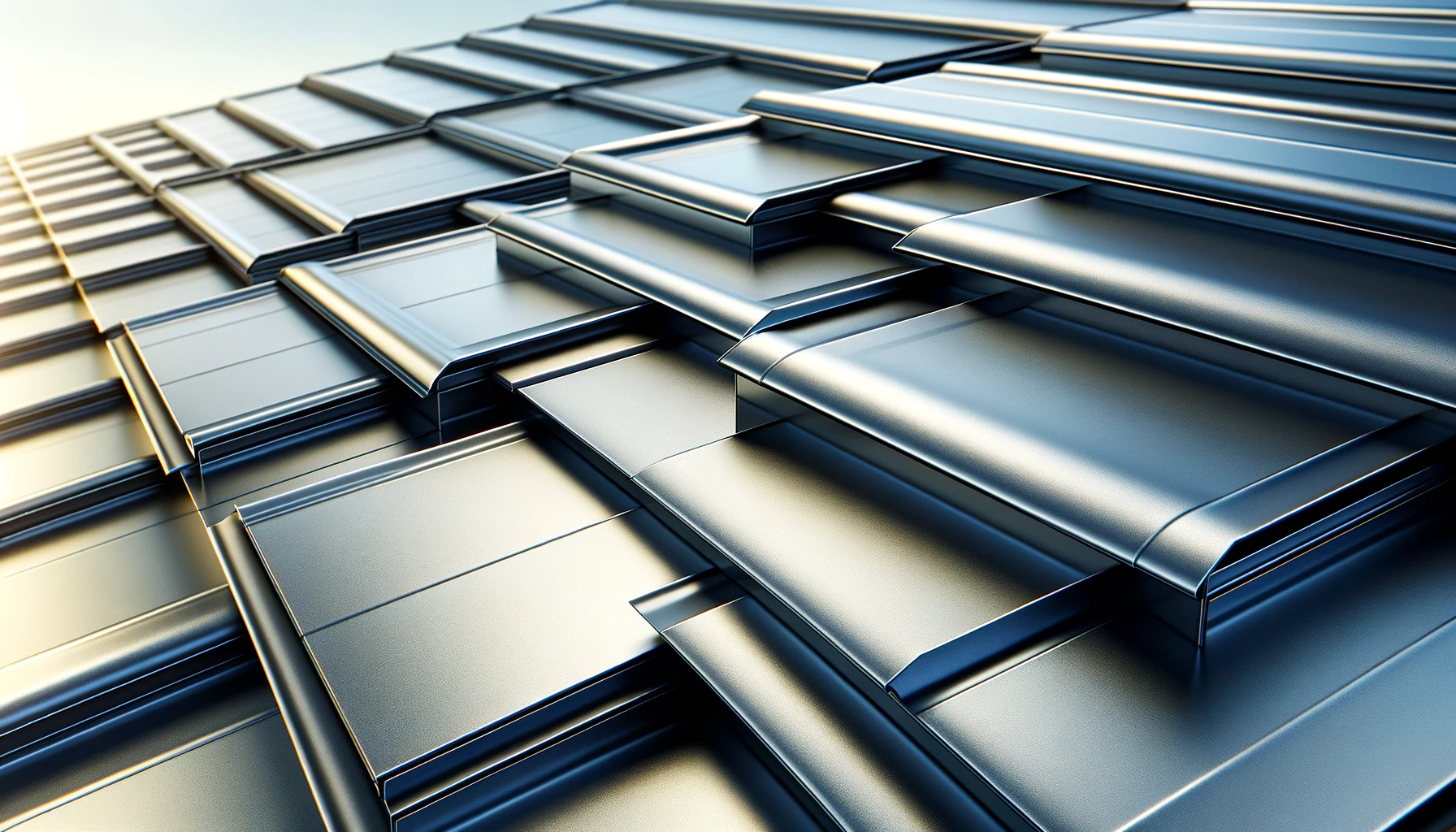

Standing seam metal roofing is a premium choice that offers durability, energy efficiency, and a sleek look. It consists of long, vertical panels with raised seams that interlock to keep out moisture, making it an ideal choice for Florida’s humid climate. These panels are not only effective in combating the elements but also provide a modern twist to the home’s appearance.

The Transformation Process

- Assessing the Structure: The first step involves assessing the original roof structure. Many 1950s homes were not designed to support heavy roofing materials. Fortunately, standing seam panels are lightweight and can usually be installed on older homes with a reinforced and clean deck.

- Choosing the Right Panels: For a 1950s home, it’s important to choose panels that complement its architectural style. Panels are available in various colors and finishes, allowing homeowners to match them with the home’s existing color scheme.

- Installation: Professional installation is key. The process involves measuring and cutting the panels on-site to ensure a perfect fit, followed by securing the panels onto the roof using a concealed fastener system. This method not only enhances the roof’s weather resistance but also maintains a clean, streamlined look.

Benefits of the Upgrade

- Enhanced Curb Appeal: Standing seam roofs provide a modern, clean look that can significantly elevate the home’s aesthetic appeal. This juxtaposition of old and new can be striking, offering a unique character that sets the home apart.

- Increased Energy Efficiency: Metal roofs reflect sunlight, reducing heat absorption and consequently lowering cooling costs. This is particularly beneficial in sunny states like Florida.

- Durability and Low Maintenance: Metal roofs are known for their longevity, often lasting 50 years or more with minimal maintenance. This is a significant upgrade from traditional shingle roofs commonly found on 1950s homes.

- Weather Resistance: Standing seam panels offer superior protection against the elements, including heavy rain, high winds, and even fire, making them an excellent choice for the varied Florida climate.

Overcoming Challenges

- Preserving Architectural Integrity: One of the main challenges in this transformation is ensuring that the new roof does not overshadow the home’s original architecture. This requires a careful balance between modern functionality and respect for historical aesthetics.

- Neighborhood Consistency: In areas where most homes reflect a certain era’s architecture, introducing a modern element like a metal roof can be contentious. It’s essential to consider the neighborhood's overall look and feel to ensure the update blends in harmoniously.

Conclusion

Transforming a 1950s home with modern standing seam panels is more than just an upgrade; it’s a marriage of history and modernity. This roofing choice offers a practical, efficient, and aesthetically pleasing solution, ensuring that the home not only retains its historical charm but also meets the demands of contemporary living. For homeowners in Florida, where the climate can be as challenging as it is varied, standing seam metal roofing is an investment in both the home’s future and its past.

In embracing this transformation, homeowners are not only preserving a piece of history but also adapting it for a new generation, ensuring that these charming 1950s homes continue to be both relevant and functional in the modern world.

Related Posts

Keep connected… join our email list

Roofing & steel building industry information, product updates, new releases, special offers, news and more direct from our corporate office.

Contact Us

Thank you for subscribing.

We will be in your inbox soon.

Please try again later.

Copyright 2024 Mid Florida Metal Roofing Supply, Inc. | All Rights Reserved | Designed by Yeppy Marketing Agency | Privacy Policy