November 24, 2023

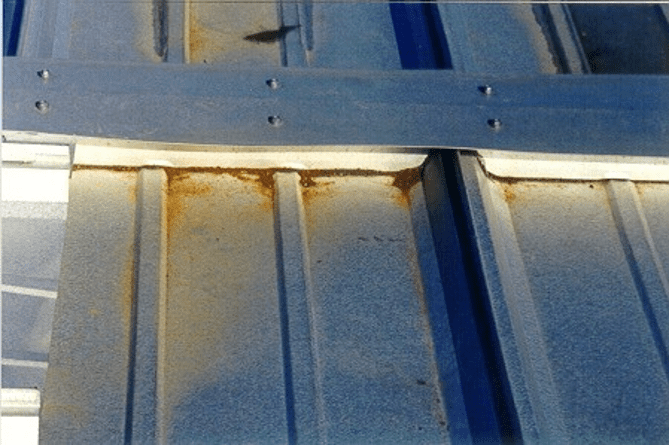

Despite the inherent durability and low maintenance requirements of metal roofing, proper care, and preventive measures are still necessary to maximize its lifespan and ensure reliable performance. A well-maintained metal roof will not only protect your property from extreme weather conditions but also enhance your building’s aesthetics, improve energy efficiency, and boost property value. However, neglecting proper maintenance could potentially result in costly repairs, lower efficiency, and reduced service life for your roof. In this blog post, we will discuss essential maintenance tips and best practices to ensure the longevity and effectiveness of your metal roofing system. By following these expert-recommended guidelines, you can enjoy a hassle-free, long-lasting metal roof that maintains its visual appeal and performance throughout its service life. We will cover topics such as regular inspections, cleaning debris, washing the roof, addressing surface damage, and replacing damaged panels. Understanding and implementing proper metal roof maintenance techniques is crucial for any property owner, regardless of whether your building is residential, commercial, or agricultural. By following the expert tips outlined in this guide, you can enjoy all the benefits of a highly durable, efficient, and aesthetically pleasing metal roof, knowing that you have taken all the necessary steps to maintain its optimal condition. 1. Importance of Regular Metal Roof Inspections Conducting regular inspections of your metal roof is an essential first step in proper maintenance, as it helps identify potential issues before they escalate. Experts recommend inspecting your roof at least twice a year and after any significant weather events, such as storms or high winds. While examining your metal roof, look for signs of damage or wear, including dents, scratches, corrosion, loose fasteners, or gaps in the seams. It’s essential to address any problems immediately to prevent further damage or costly repairs. If you’re unsure about assessing your roof yourself or have safety concerns, consider hiring a professional inspector to ensure a thorough and accurate evaluation. 2. Cleaning Debris and Washing Your Metal Roof Keeping your metal roof clean and free of debris not only improves its appearance but also maintains its performance. Debris accumulation, such as leaves, branches, or dirt, can trap moisture and create a breeding ground for mold or algae, posing a threat to your roof’s longevity. To clean your metal roof, use a soft-bristle brush or a non-abrasive cloth to gently remove dirt and debris buildup. If necessary, mix a mild detergent solution in a bucket of water for a more thorough cleansing. Depending on your roof’s size and slope, you may need a ladder or an extendable brush to reach all areas safely. Rinse your roof thoroughly with water after cleaning, ensuring no residue remains. Never use abrasive tools or high-pressure water, as these can cause damage to your roof’s protective coating or panels. If your roof has a considerable buildup of mold, algae, or moss, consult a professional cleaner to address the issue effectively and safely. 3. Addressing Surface Damage and Protective Coatings Over time, metal roof panels and coatings may experience wear or damage due to environmental factors and weather conditions. Regularly examine your roof for signs of paint discoloration, chipping, flaking, or rust. If you notice any surface imperfections, take prompt action to resolve them, as they may lead to moisture infiltration or compromise your roof’s structural integrity. To treat minor paint damage, use a touch-up paint that matches your roof’s color and carefully follow the manufacturer’s instructions for best results. If you notice rust or corrosion, lightly sand the affected area until smooth and apply a rust-inhibiting primer before repainting. For more extensive damage or if you’re uncomfortable with DIY repairs, consider hiring a professional roofing contractor to handle the issue, ensuring a reliable and durable solution. 4. Identifying and Replacing Damaged Metal Roof Panels In some cases, damaged metal roof panels may require replacement to maintain the roof’s integrity and performance. Identifying signs of damage, such as severe dents, punctures, or extensive corrosion, is essential to prevent leaks and potential structural issues. When replacing a damaged panel, professional installation is highly recommended to ensure proper alignment and sealing. A roofing contractor will be able to assess any underlying damage, obtain matching replacement panels, and install them correctly, guaranteeing a high-quality and long-lasting repair. If you choose to tackle panel replacement on your own, ensure you follow the proper safety precautions, including using fall protection equipment and working with a partner on the ground to assist you. Ensuring a Long-lasting, High-performing Metal Roof Proper metal roof maintenance is essential to ensuring a long-lasting, efficient, and visually appealing solution for your residential, commercial, or agricultural property. Regular inspections, cleaning, addressing surface damage, and, if necessary, replacing damaged panels are all critical steps in maintaining your metal roof’s integrity and performance. By following the expert tips in this guide, property owners can enjoy the numerous benefits of a well-maintained metal roof, such as enhanced energy efficiency, increased durability, and added curb appeal. Mid Florida Metal Roofing Supply, Inc. takes pride in offering top-quality metal roofing materials and expert advice, ensuring that you can confidently care for your metal roof and maximize its lifespan.